| Techno June 2023 |

|

||||

|

|

|

|||

|

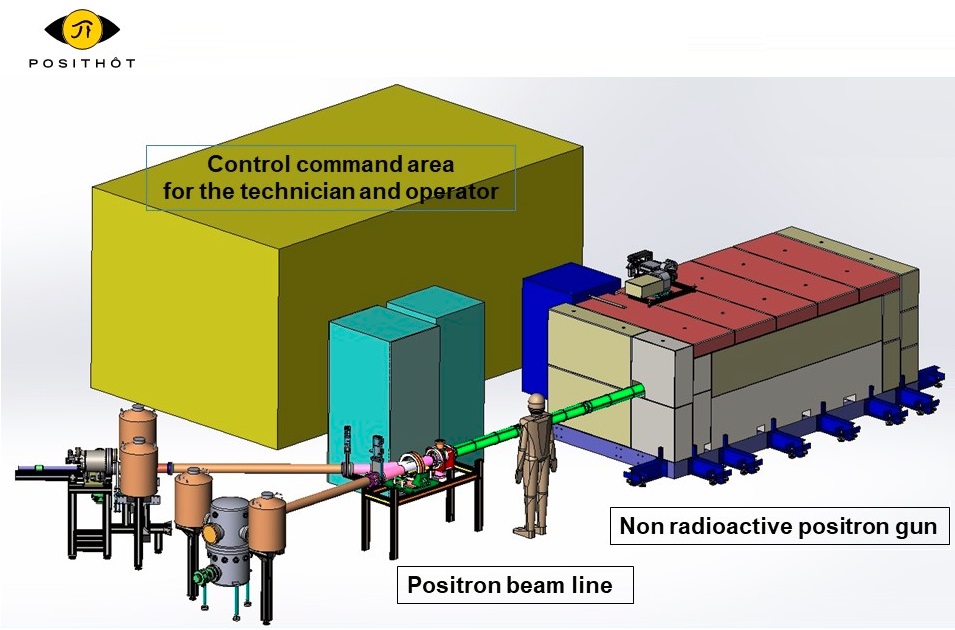

The generator of

Posithôt, also named the « gun ». Inside

this mysterious black box stands a micro accelerator which delivers a

continuous beam of positrons - the anti-particles of electrons. Anti

matter is now available on Earth and comes out in compact casing !

Industrial clients are going to be happy ! |

|

||||

|

There have been times none believed

anti-matter could exist, until mankind discovered it in cosmic rays

then created anti-particles in accelerators. From that time on

speculations grew hard upon what could be done with those strange

particles coming out of nowhere. Success came when physicists choose to

use them to probe our existing matter, with astonishing results! As

matter annihilates anti-matter when they meet, anti-matter shows an

incredible ability to live a little longer when it flies through matter

voids revealing by the way all matter defects. Anti-matter spectroscopy

was born and became for some time a curiosity in the lab: the thing

able to see the holes in the full. Then came Posithôt, a special

instrument based on positron emission - and a spin-off of the French

nuclear research administration (CEA) - which was designed to allow

engineers to probe matter vacancies and map out cracks in advanced

materials and cutting-edge parts. A real industrial tool delivering a

constant beam of anti-particles for steady quality control that would

make our technological world safer! And the good news is that this

anti-particle generator is very compact and non-radioactive when out of

duty - which in turn allows an easy servicing in the dead times.

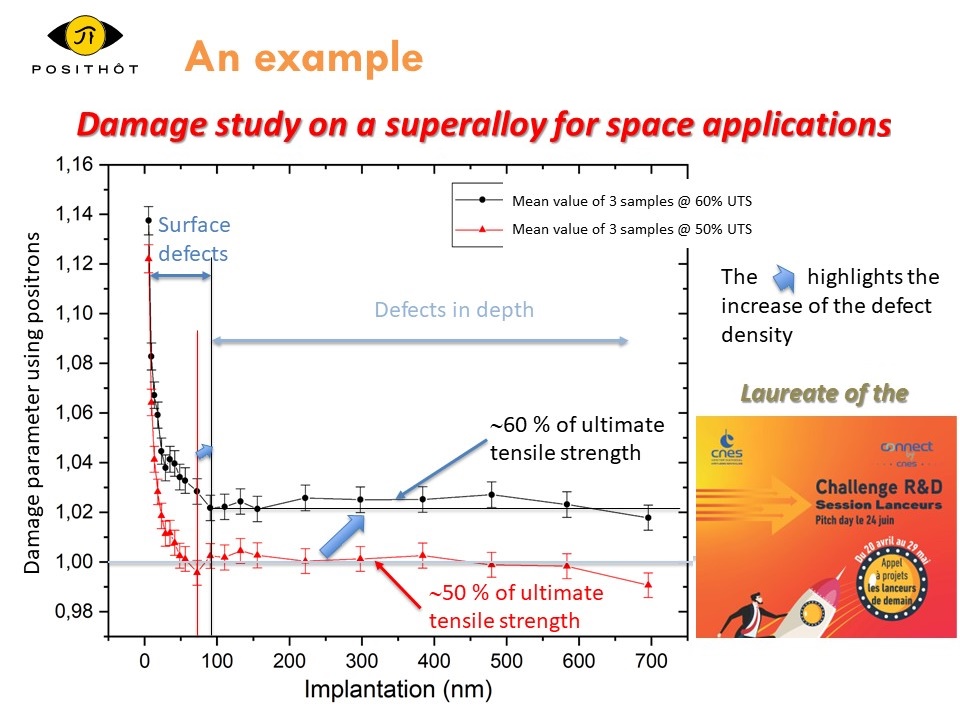

ConsultingNewsLine has met Jean Michel Rey and Pierre Bregeault of Posithôt to know more about this brand-new high technology… ConsultingNewsLine: Jean-Michel Rey, Pierre Bregeault, Thank you to welcome us at Posithôt for a visit to the first compact and non-radioactive positron generator available for industrial control on a routine basis. Where does that technology come from and how does it work is my question to get started. Probably Jean-Michel Rey, who is the Head physicist of the team, would like to answer ?  Jean Michel Rey : For sure. Posithôt develops the industrial applications of a spectroscopy based on the annihilation of positrons (positons in French). And positrons are the anti-particles of the electrons, as anticipated by Dirac in 1928 through his famous equation and soon discovered by Carl Anderson in cosmic rays in 1932. Positrons features and especially their mass and charge were precisely measured by French physicist Jean Thibaud as early as 1933. And clearly the positrons appeared to be the anti-particles of the electron: same mass but positive charge ! In 1934 Frédéric and Irène Joliot-Curie bombarded aluminum foils with alpha particles (emitted by polonium) which resulted in Phosphorus 15 a radio-isotope which emits positrons, and incidentally that was the first artificial radioactivity known so far. Since then, positrons have been created by different means - initially as transitory species in large particles accelerators then for lab use with linear proton accelerators and cyclotrons and also in nuclear reactors. And this is how nowadays isotopes such as Nitrogen 13, Fluorine 18 or Sodium 22 are made. These isotopes naturally emit Beta + radiations which are in facts positrons. However from creating positive electrons to having a sound scientific and industrial applications the journey has been very long and it must be understood that what we deal with is anti-matter which makes things very different because positrons annihilates whenever they encounter electrons, and matter is full of electron clouds, so they easily disappear, producing by the way powerful pairs of gamma photons. This said it is this annihilation that we have profited from as gamma photons can easily be detected which in turn makes the main concept behind the positron spectroscopy. What we do here at Posithôt is basically to detect gamma photons that result from positron annihilation anytime positrons hit matter. Then we analyze this photon emission in time and energy in the range 100 eV to 550 000 eV. But we first have to produce these positrons, and to escape the constraints of radioactive materials, we have replaced the beta+ emitters by a non-radioactive accelerator-based positron generator. That is basically what Posithôt does! ConsultingNewsLine: What can be seen through these positron collisions and subsequent photon analysis ? Jean Michel Rey : What can be seen with this apparently destructive effect is - quite the contrary - a non-destructive observation of matter structure and its defects. Because the great discovery, the « miracle » behind - which is the second concept behind positron spectroscopy - is the fact that the complex trajectory of positrons in matter, that kind of zig zags of positrons in the matter, is highly determined by the defects they encounter which very much increase their life time before annihilation. And this in turn allows us to probe the micro defects of matter: atom vacancies, dislocations, cracks, pores... Thus positron spectroscopy is surprisingly a « defect spectroscopy » and we can easily imagine the huge scientific and industrial applications resulting from it... ConsultingNewsLine: So, what can those applications be? Pierre Bregeault, Head of marketing and communication at Posithôt, would you mind telling us a little more on that topic ?  Pierre Bregeault : It’s my pleasure. Different kind of materials can be submitted to positron spectroscopy from metals to polymers. Applications range from fundamental research to industrial quality control. For each material choosen the analysis aims at detecting the most characteristic defects. From the tiniest to the utmost structured ones. These defects can be displaced atoms in nuclear fuels and claddings submitted to intense radiation in nuclear reactors. It can also be atom vacancies or dislocations in semiconductor wafers, a difficult state of things if you make processors and solar cells for space activity. It can also be cracks and percolating networks of such cracks in metal parts for which any break up becomes critical to safe operations, which is the case for jet engine compressor blades, helicopter turbines and rotors, airframes and aircraft metal fittings. Same for drive shafts in marine applications, drill pipes and roller bits for oil exploration, wind and water turbine shafts for wind farms and offshore power production… Anytime parts are critical to passenger safety, equipment security or continuity and rate of industrial activity in harsh environment and remote locations defects and crack analysis becomes essential... and posithôt can do that. So Posithôt is definitively one of the finest NDT (Non Destructive Testing) technology, and can be considered as a Metrology regarding its sensitivity. ConsultingNewsLine : Can that technology be applied to all serial parts ? I mean, nowadays we are all using high tech objects that can break anytime, cell phones, laptops... but so low priced that to high quality control them, frankly they are not worth it... Pierre Bregeault : Right. Positron spectroscopy is mandatory only for cutting edge parts, such as rocket engines or unique devices fitted in satellites or some new parts in racing cars. Same for highly priced small series of critical parts for which a serial control can really be envisioned which is the case for military industry, large guns and shell manufacturing and will probably be the case for air taxis, what we call the eVtols, etc... But for most technologies sold to the average customer it is the manufacture process that has to be secured. You indicated cell phones. Some batteries tend to take fire in cell phones but we cannot test all of them, it’s too expensive. Thus small series of parts made under specific and variable conditions have to be tested to determine which process conditions are the best and give the best quality outcome. So alongside the systematic control of highly critical and highly costly parts there is room for process evaluation to support the industrial demand of quality goods for the customer. Another example is drones. Today small drones as eVitols must not crash in populated areas but their price is far too low for a systematic control of all their parts upon costly tests, so what we do propose is the optimization of the critical parts manufacturing process, for batteries, magnets, shafts, bearings etc... This is where Posithôt can also provide a superior support. ConsultingNewsLine: The materials mentioned so far were mostly solid, rodlike or coming as foils… Are powders also eligible for positron spectroscopy ? Pierre Bregeault : Definitively yes, even if sometimes it’s a little more tricky, and this is mainly the case for the chemical industry where most reactants come as powders and especially for heterogeneous catalysis for which the specific surface area of pores can be measured as well as the open fraction of the pores to the outside of the seeds which is decisive for an efficient catalysis. ConsultingNewsLine: and we all know that catalysts in refinery units can cost up to hundred of millions euros for a single replacement batch. Catalysts duration and efficiency often determine operating costs... Pierre Bregeault : Absolutely and the ROI, the return on investment is what we focus on with potential clients. Jean Michel Rey : Before we land in the economic part of the job I would like to add a scientific view on that point of porosity. Porous materials are not only the case of catalysts but also that of batteries and fuel cells electrodes or that of hydrides for hydrogen storage, and same for desalination membranes. And it can be demonstrated that independent pores on one side, linked pores on the other side and pores open up to the outside all give a different signal when analyzed in time and energy by positron spectroscopy. So we can discriminate them and better know the structure of the material and its ability to interact with a gas or a liquid, which is the core of all chemical processes. That makes Posithôt a formidable tool to study and control new materials in electronics, opto-electronics, electro-chemistry, chemistry and power supply. Especially at a time we discover new materials nearly every days and produce older ones with new textures at a high rate. Think of polycrystalline or porous silicon for instance, Gallium arsenide, multilayered semiconductors, zeolites, ceramics polymer membranes and composites...  Copyright Posithôt 2023 The complete Posithôt apparatus, with its positron generator, its beam lines fitted with two experiments chambers plus the control command room. All parts are accessible for the operator, even when the generator is on, the radiation being strictly confined inside the shielding of the generator ConsultingNewsLine: What about 3D printing? Pierre Bregeault : This is a new field of activity with a lot of opportunities. Industrial prototypes as well as small part series can be made this way. In the automotive sector and the aerospace metallic parts made by 3D printing - most done by metal powder sintering - defaults can occur and porosity can impair the resulting parts. Positron spectroscopy can also here prove valuable to detect these impairments. So this is absolutely a new domain of investigation for Posithôt. ConsultingNesLine: Thus we can use positron spectroscopy to study new materials and their porosity. But let me be the devil’s advocate. We have already numerous technologies to probe defects in matter, Gas Adsorption, Die Penetrant Testing, Eddy currents, Ellipsometry, Ultrasound Imagery, Electron and X-ray Spectroscopies... What makes Positron spectroscopy a better technology and the new tool for the 21rst century? Jean Michel Rey : The different technologies you mention are for a few ones only usable for surface analysis, such as gas adsorption, die penetrant testing, eddy currents or ellipsometry. For the other ones used for bulk analysis or relying on electrons beams, they are destructive when used in the energy range necessary for the observation of the finest defects. For ultrasound imagery or K rays which have a very low resolution, it cannot even probe the smallest defects. So in the defects scale we are interested in which starts from small holes lacking a million atoms down to only one atom - in other words a simple lattice vacancy - clearly positron spectroscopy is the only non- destructive technology (NDT) available. It also shows an easy handling despite a more complex computer data treatment. ConsultingNesLine : Easy handling is generally a euphemism for nuclear technologies. Could you tell us more on how you generate your positrons, carry out your experiments and why the whole device gives superior results and easy handling ? Jean Michel Rey : Posithôt is a very compact positron generator in which we accelerate electrons with microwaves and let them interact subsequently with a target crystal which nucleus deviate strongly the fast electrons that come too close to them. This leads to a strong gamma photon emission due the deceleration of the electrons, what is referred to as « bremstrahlung » in physics with a German word, namely a radiation of breaking, which can lead to the spontaneous emission of electron – positron pairs whenever the photons energy is over 1,2 Mev, which is the exact energy threshold to create a pair of particles-anti-particles according to the equation of relativity E=mc2. Once we have positrons we can separate them from electrons as they don’t bare the same electrical charge, and select their energy. This is done through electrostatic and magnetic filters and collimators which are basic devices of particles physics. This said the whole device and the guidelines that carry the positrons to the experiment chamber must work under a perfect vacuum. But this is also standard. This complete technology is unique and has been subject to patenting. ConsultingNesLine: So you produce gamma rays within the positron generator and ultimately you will also get some gamma rays to detect your positron annihilation in the experiment chamber. Jean Michel Rey : Exactly and this is why the generator is surrounded by lead plates and concrete walls when it operates. But the good news is that there is no nuclear reaction nor any neutron radiation involved in the process. Thus once the experiment is over and the generator stopped all the high energy photons disappear. We don’t have any radioactivity or activated material left in the device and the generator. It is nuclear free. We can then handle it with no special protection in the dead time. It is as easy as maintaining an X-ray spectrometer. ConsultingNewsLine: And you guarantee that these are the same safe conditions as in the experiment chamber ? Jean Michel Rey : Provided that you are not working on radioactive materials it is the same. We inject low energy positrons into the samples under experimentation and detect the gamma photons emerging at wavelength (~ 500 Kev) for which they don’t interact with nucleus (threshold at 1 Mev) or core electrons (X-ray energy), so we don’t have the least nuclear reaction nor X-ray fluorescence in the sample under experimentation and the only limitation is to protect the operators from the gamma ray itself during the experiment and the positrons or photo-electrons that could escape but which are easily stopped by the metallic casing. So this technology is clearly fully non-destructive, for the sample, easy to handle for the experimentalist, and can probe micro defects in the range 1 to 10 power 6 atoms that are critical for cracks initialization in metals or to start semi-conductors impairment. So if some classical technologies will continue to be used for common defects on the surface or for large cracks in the bulk, the positron spectroscopy will be the ultimate weapon to detect as early as possible the finest ones, far before they crosslink and make a deadly network. So Posithôt is the only technology available today to see the most critical defects in mechanical parts or electronics materials which makes it absolutely strategic in our high-tech world and a world of intense mass transportation. It’s a cutting-edge technology.  Copyright Posithôt 2023 Example of a data string recorded by Posithôt : The damage parameter profile of a superalloy used for space applications. The parameter measured as a function of depth shows the consequences of the stress level applied to the samples during a fatigue test. It highlights open microcracks below the surface. ConsultingNewsLine : A cutting edge technology that comes at a high price. How much does it cost in fact ? And what is the Posithôt ROI ? Pierre Bregeault... Pierre Bregeault : Posithôt in the configuration you see today costs approximately 3 million euros. And for a commercial machine, fitted with an adapted experiment chamber, fully operational on the client’s site, we would be closer to 3,5 million euros, this including building work and team training. For operations on the client’s site we are currently thinking of renting the device with its crew as was done at the time of main frame computers provision. Different kind of contracts could be proposed from hiring to leasing. It must be understood that this kind of machine, which a new one will soon be installed in a truck, requires a high level of operability to be profitable. A string of data costs from 5000 euros to 50 000 euros, depending on the complexity, comparable with medical imagery. And for research as well as industrial application it must be considered days of work at the price of engineering. So we thing big corporations could profit from it as well as small enterprises grouped in syndicate labs. Same for fundamental research and R&D for which joint facilities could be developed, and this all over the world as this technology is unique. In term of ROI we can provide potential clients with assessments depending on their business processes. ConsultingNewsLine: Again I will try to be the devil’s advocate. Faced with such a significant cost, could we try to perform positron spectroscopy with simpler technologies such as radioactive sources as it is done for medical PET Scans. You mentioned N13, F18 and Na22 Beta + sources at the beginning of this interview. Jean Michel Rey : This is an old fashioned way to do positron spectroscopy, even if for medical use with PET scan it is of the highest interest. But let’s face this natural contender. The use of radio-isotopes, which means materials whose radioactivity decreases between experiments and also during the experiments themselves makes it unsuitable for precise and repetitive industrial applications. For medical ones about 10 artificial radionuclides such as Carbon 11, Nitrogen 13 or Oxygen 15 are used among which Fluorine 18 is the most commonly selected (95 %.) They all are short-lived positron emitting radio-isotopes [11C (T1⁄2 = 20.4 min), 13N (T1⁄2 = 10 min), 15O (T1⁄2 = 2 min)] and for the mentioned Fluorine 18 which half-life is only 2 minutes, suitable for Positron Emission Tomography (PET Scan) but far too short for precise material analysis, the wrong thing is that they are all produced using irradiation of natural targets, thus generating radioactive wastes. This mean you need a synchrotron or linear accelerator to accelerate your protons which is not only a complicated way to make short lived species but also a far more costly process than to get a positron beam with the Posithôt generator. And for longer lived radioisotopes such as Zr 89 (T1⁄2 = 58H) it is not any better as you also need a proton source (and for some radio-isotopes a nuclear reactor). Same for Na22 used in labs to perform positron irradiation. So in our development scheme, before embarking on the « electron to photon to positron » way used by Posithôt to produce high flow of positrons we have compared all the different ways of producing positrons and Posithôt proved to be the most efficient and the cheapest one to deliver strong and steady beams for industrial use. And we succeeded in making it compact. ConsultingNewsLine: As this interview comes to its end I would like to thank you for this introduction to the Posithôt technology and perhaps try to use the remaining time to know a little more on Posithôt as an enterprise, its goals for the future and also its first successes. Jean Michel Rey : Posithôt is a private company, a spin-off of the CEA (French nuclear administration) which aims at building, commercializing and providing services around the Posithôt technology. It is 10,5 % owned by CEA and the rest by private shareholders among which the creators of the technology. We are located on the Les Ulis Techno Park, so very close to the Saclay nuclear center and the scientific compound of Orsay and Saclay plateau, a quarter of and hour away from Orly Airport and Toussus Le Noble business airfield and an hour away from downtown Paris by fast regional trains or the highway. Today we have strong relations with Safran, Nexter, the Ariane group, and the CNES (French Space administration) and have already won contracts with the French Ministry of Defense. A second positron emitter is foreseen for portable use on a truck and we hope to sell a few ones in the near future. But as already said, providing services in the broadest sense is what we aim to deliver, be it by implementing Posithôt in large corporations and providing in-house support, or subcontracting tests in our own premises or developing joint facilities for research institutes and business combinations. Pierre Bregeault : And if we had to help your readers keep just one idea in mind it would be that Posithôt really is the new tool for the new century, compact, non-radioactive, with high and steady flow, able to provide unprecedented access to the microstructure of defects in materials and thus to bring superior nondestructive testing (NDT), quality control and prevention control and in a broader sense able to help them or their clients to secure what has become paramount to industrial activity : the MRO, Maintenance, Repair and Operations and the MCO for critical operations, retro processing and retro composition. Words collected by Bertrand Villeret Chief Editor, ConsultingNewsLine bvilleret2@aol.com  < to the French

version < to the French

versionContacts: Jean-Michel REY Jean-michel.rey@posithot.com www.posithot.com Pierre Bregeault pierre.bregeault@posithot.com https://www.posithot.com |